High precision manufacturing of shofu diamond burs through computer automatic robotic technology gurantees uniform distribution of precise propertion of natural diamond particles onto a single high grade stainless steel shank for high accuracy and effortless cutting efficiency every time

Multi- coating technique?coupled with special surface treatment reinforces the structural integrity of the diamond bur for consistent clinical performance , greater durability and minimized clogging.

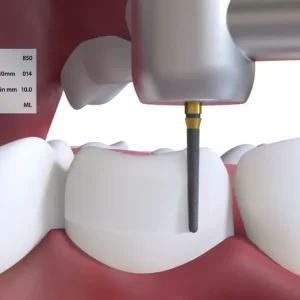

Shofu diamond bur shank?is smooth with accurate dimensions for a precise fit with no vibration and minimal strain on the turbine to assure durability of the handpiece cartridge.

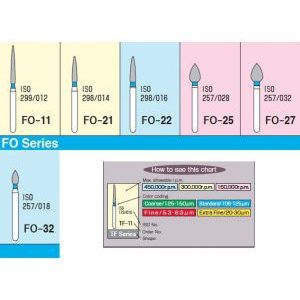

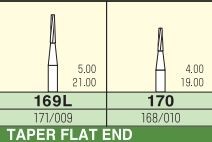

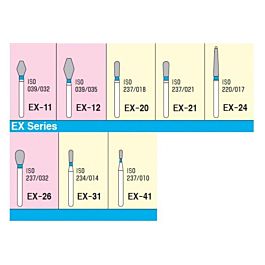

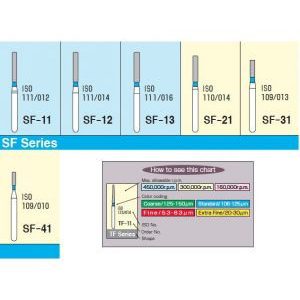

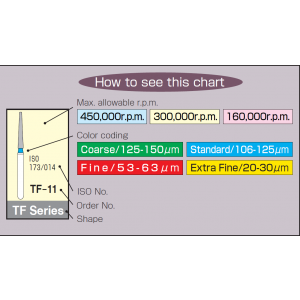

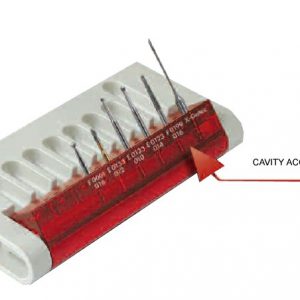

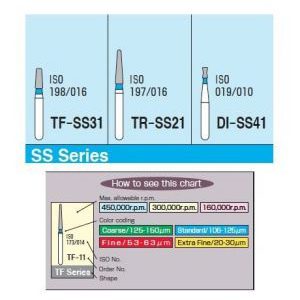

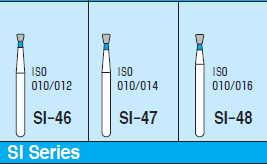

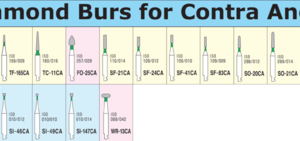

Shofu diamond comprises the standard range of shapes in different grits as well as some special burs such as MI Diamonds, TPE burs, Hybrid / T&F Hybrid Points for various substrates – enamel , porcelain , composite, GIC, etc. and specific diamond disks/burs for laboratory use.

Coarse Grit (Green Band) –?Utilizes larger diamond particles compared to regular grit for gross reduction of natural tooth or faulty restorations. 8 different shapes are available.

There are no reviews yet.